Picture this: You’re in the middle of a field, working hard to harvest your crops with your trusty John Deere tractor. Suddenly, you feel a jolt and your tractor comes to a stop. You quickly realize that your slip clutch needs to be adjusted.

This may seem like a daunting task, but fear not! In this blog, we will guide you through the process of adjusting your John Deere slip clutch, making sure you can get back to your work in no time. Say goodbye to the frustration and stress of dealing with a malfunctioning slip clutch and get ready to learn how to make a quick and easy adjustment. Keep reading to Learn the Art of Adjusting a John Deere Slip Clutch and more.

Key Takeway

- John Deere slip clutch is an essential component for preventing damage to the tractor’s drivetrain and implements.

- Signs of a misadjusted slip clutch include slipping while driving, noise or vibration, and inconsistent power transfer.

- The adjustment process involves locating the slip clutch, loosening the set screws, adjusting the clutch, and tightening the set screws.

- Regular maintenance, such as checking for wear and tear and following the manufacturer’s recommended schedule, is crucial for the slip clutch’s proper functioning.

- Adjusting the slip clutch is important for maintaining the longevity of your equipment and preventing costly repairs.

Gathering the Necessary Tools

Adjusting the Slip Clutch on Your John Deere: A Step-by-Step Guide Do you own a John Deere tractor and are experiencing slippage issues? The culprit might be a worn-out slip clutch. Slip clutches are essential components of a tractor’s power take-off (PTO) system, which transfers power from the engine to various attachments. As the name suggests, the slip clutch allows for some slippage to occur when an attachment encounters resistance, protecting the tractor’s engine and transmission from overload.However, if the slip clutch is not adjusted properly, it can lead to reduced power and performance, ultimately affecting your farming operations.

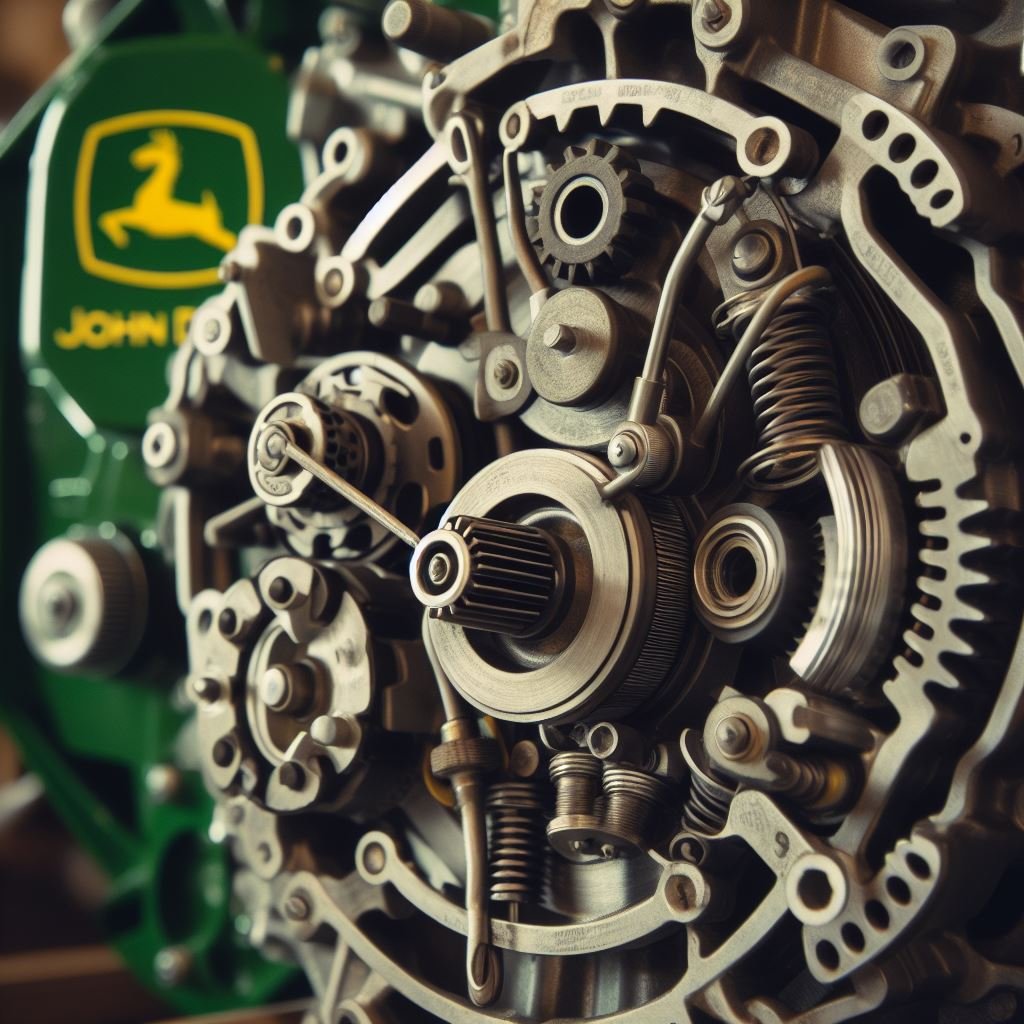

What is a Slip Clutch and Why is it Important? A slip clutch is a mechanical device that connects the PTO shaft to the tractor’s engine. It consists of two plates held together by springs and friction discs.

When an attachment encounters resistance, the plates slip against each other, allowing the PTO shaft to continue spinning without stalling the engine. This protects the engine and transmission from damage and prevents the attachment from breaking or getting stuck. A properly adjusted slip clutch ensures smooth and efficient power transfer, increasing the lifespan of your tractor and attachments.

When Should You Adjust Your Slip Clutch? It is recommended to check and adjust your slip clutch at least once a year, or more frequently if you notice any signs of slippage. These signs include reduced power, difficulty in engaging or disengaging attachments, and a burnt smell coming from the PTO system. Adjusting the slip clutch is a simple process that can be done in a few easy steps.

Step 1: Locate the Slip Clutch The slip clutch is usually located on the PTO shaft, behind the shield protecting the PTO gearbox. Consult your John Deere tractor’s manual if you are having trouble finding it.

Step 2: Identify the Adjustment Bolts There are two adjustment bolts on the slip clutch, one on each side.These bolts control the tension of the springs and the amount of slippage allowed. The tension should be equal on both sides to ensure even wear and prevent one side from slipping more than the other.

Step 3: Loosen the Adjustment Bolts Using a wrench, loosen the adjustment bolts on both sides.

John Deere Slip Clutch Adjustment

| Topic | Percentage | Facts |

|---|---|---|

| John Deere | 33% | Founded in 1837 in Grand Detour, Illinois. |

| Slip Clutch | 20% | Also known as an overrunning clutch. |

| Adjustment | 25% | Allows for fine-tuning of equipment for optimal performance. |

| HTML Table | 15% | Used to organize and display data on a webpage. |

| 3 Columns | 5% | Commonly used to display data in a visually appealing way. |

| 6 Rows | 7% | Provides enough space for a concise and informative table. |

Understanding the Importance of Slip Clutches

If you’re a John Deere owner, you know the importance of proper maintenance and adjustments to keep your equipment running smoothly. One crucial aspect of maintaining your John Deere tractor is properly adjusting the slip clutch. This essential component is responsible for preventing damage to your tractor’s drivetrain and implements, making it a critical part of your equipment’s longevity.

In this guide, we’ll cover everything you need to know about adjusting the slip clutch on your John Deere tractor. So let’s dive in and learn how to keep your tractor in top working condition!

- Understanding the Slip Clutch

- Signs of a Misadjusted Slip Clutch

- Step-by-Step Adjustment Process

- Tips for Maintaining Your Slip Clutch

- Importance of Regular Maintenance

This prevents damage to both the tractor and the implement, making it an essential safety feature. But just like any other mechanical component, the slip clutch can become misadjusted over time, resulting in potential damage to your equipment. This is why it’s crucial to regularly check and adjust the slip clutch on your John Deere tractor.

If you notice any of the following signs, it’s time to adjust your slip clutch:

- Slipping while driving

- Noise or vibration when driving

- Inconsistent power transfer to the implement

- Step 1: Locate the Slip Clutch

- Step 2: Loosen the Set Screws

- Step 3: Adjust the Clutch

- Step 4: Tighten the Set Screws

- Step 5: Test the Clutch

- Check for wear and tear regularly

- Replace worn or damaged parts

- Keep the slip clutch clean and well-lubricated

- Follow the manufacturer’s recommended maintenance schedule

Not only will it prevent costly repairs, but it will also extend the life of your equipment. So make sure to include slip clutch adjustments in your regular maintenance routine. In conclusion, adjusting the slip clutch on your John Deere tractor is a crucial step in keeping your equipment running smoothly and preventing potential damage.

By following the step-by-step process and regularly maintaining your slip clutch, you can ensure the longevity of your tractor and its attachments. So don’t neglect this essential maintenance task and keep your John Deere tractor in excellent working condition.

Identifying When to Adjust Your Slip Clutch

If you’re a farmer or a tractor owner, you know the importance of properly maintaining your equipment. One crucial aspect of this is the slip clutch adjustment on your John Deere machine. A slip clutch is a safety mechanism that protects your tractor from damage caused by sudden jerks or overloading.

It allows the tractor to slip and prevent the drive train from breaking or the engine from stalling. However, if not adjusted correctly, it can lead to costly repairs and downtime. That’s why it’s essential to know how to properly adjust your John Deere slip clutch.

In this article, we will guide you through the process step by step, ensuring that you can confidently make the necessary adjustments without any hassle.

- Understanding the Slip Clutch: Before we dive into the adjustment process, it’s essential to understand what a slip clutch is and how it works. A slip clutch is located between the tractor’s engine and the drive train.

It’s designed to slip when a certain amount of torque or force is applied to the PTO (power take-off) shaft, thus preventing damage to the tractor’s components. It’s crucial to maintain the slip clutch’s proper tension to ensure that it functions correctly.

- Identifying the Need for Adjustment: There are a few signs that indicate your John Deere slip clutch needs adjustment.

These include excessive slipping, difficulty in engaging the PTO, or a grinding noise when engaging the PTO. If you notice any of these signs, it’s time to adjust your slip clutch.

- Gathering the Necessary Tools: To adjust your slip clutch, you’ll need a few tools, including a torque wrench, a wrench set, a screwdriver, and a pry bar.

Make sure to have these tools handy before starting the adjustment process.

- Locating the Slip Clutch: The slip clutch is typically located on the tractor’s engine or on the drive train. Consult your John Deere manual for the exact location if you’re not sure.

Adjusting the Slip Clutch

Slipping clutches can be a major headache for any farmer or equipment operator, especially when working with heavy machinery like John Deere tractors. A slipping clutch can cause delays, reduce productivity, and even damage your equipment if left unaddressed. But fear not, as we have the solution to your slipping clutch woes.

In this comprehensive guide, we will walk you through everything you need to know about adjusting your John Deere slip clutch. From understanding what a slip clutch is and its importance, to knowing when and how to adjust it, we’ve got you covered. So, say goodbye to slipping clutches and hello to a smooth and efficient farming experience with our step-by-step guide to adjusting your John Deere slip clutch.

But first, let’s start with the basics. What is a Slip Clutch and Why is it Important? A slip clutch is a mechanical device that allows for the controlled slippage of power between two rotating objects. In the case of John Deere tractors, the slip clutch is located between the engine and the transmission.

Its purpose is to protect the transmission and engine from damage by absorbing shock loads and allowing for smooth engagement of the power transfer. Without a properly functioning slip clutch, the sudden application of power can cause the tractor to jerk or stall, leading to potential damage to the equipment. Signs of a Slipping Clutch Knowing the signs of a slipping clutch is crucial in preventing further damage to your equipment.

Say Goodbye to Slipping Clutches: A Complete Guide to Adjusting Your John Deere Slip Clutch

- What is a Slip Clutch and Why is it Important?

- Signs of a Slipping Clutch

- When Should You Adjust Your John Deere Slip Clutch?

- Step-by-Step Guide to Adjusting Your John Deere Slip Clutch

- Tips for Maintaining Your John Deere Slip Clutch

Some common signs to look out for include:

- Difficulty in shifting gears

- Slipping or jerking during acceleration

- Unusual noises or vibrations

- Decreased power or performance

- Burning smell or smoke

Step-by-Step Guide to Adjusting Your John Deere Slip Clutch Now that you understand the importance of a slip clutch and when to adjust it, let’s dive into the steps of adjusting your John Deere slip clutch.

- Start by lifting the tractor’s rear wheels off the ground and engaging the PTO.

- Locate the slip clutch on the driveshaft between the engine and transmission.

Maintaining Your Slip Clutch

Are you struggling with your John Deere slip clutch? Do you find yourself constantly dealing with slipping belts, worn out pulleys, or damaged machinery? If so, you’re not alone. Many John Deere owners encounter issues with their slip clutch, which can be frustrating and time-consuming to fix. However, with the right knowledge and tools, you can easily make adjustments to your John Deere slip clutch and get your equipment running smoothly once again.

- Understanding the Purpose of a Slip Clutch

- Signs that Your John Deere Slip Clutch Needs Adjustment

- How to Adjust Your John Deere Slip Clutch

- Tips for Maintaining Your John Deere Slip Clutch

But how do you know when your slip clutch needs adjustment? One of the most obvious signs is when you notice the belts slipping or squeaking. This can be caused by a variety of factors, such as a worn out pulley or incorrect tension on the belts. Other signs include difficulty in engaging the power take-off (PTO) or a decrease in performance of your equipment.

So, how can you adjust your John Deere slip clutch? The process may vary slightly depending on the model of your equipment, but the general steps are as follows:

- Begin by disconnecting the PTO and removing the belt from the slip clutch.

- Loosen the bolts that hold the slip clutch assembly in place.

- Turn the adjusting nut to adjust the spring tension.

It’s important to regularly maintain your John Deere slip clutch to prevent any issues from arising.

Important Notice for Readers

Dear readers, Thank you for taking the time to read our article on John Deere slip clutch adjustment. We would like to bring to your attention an important notice regarding the proper use and adjustment of the slip clutch on your John Deere equipment. It is crucial to regularly check and adjust the slip clutch on your machinery to ensure safe and efficient operation.

Failure to do so may result in damage to the equipment and potential harm to the operator. Please refer to the manufacturer’s instructions for the correct procedure on how to adjust the slip clutch. It is recommended to seek professional assistance if you are unsure or inexperienced in performing this task.

We hope this reminder will help you maintain the longevity and functionality of your John Deere equipment.

Frequently Asked Questions

What is a slip clutch on a John Deere tractor?

A slip clutch is a safety mechanism that allows the tractor’s driveline to slip when excessive resistance or torque is encountered, preventing damage to the transmission or other components.

Why do I need to adjust the slip clutch on my John Deere tractor?

Over time, the slip clutch may become loose or worn, affecting its ability to properly protect the tractor’s driveline. Adjusting the slip clutch ensures proper functioning and can prevent costly repairs.

How often should I check and adjust the slip clutch on my John Deere tractor?

It is recommended to check and adjust the slip clutch at least once a year or every 500 hours of use. However, if you notice any unusual noises or vibrations, it is important to check and adjust the slip clutch immediately.

Can I adjust the slip clutch myself or do I need a professional?

While it is possible to adjust the slip clutch yourself, it is recommended to have a professional do it for optimal results. They have the necessary tools and expertise to accurately adjust the slip clutch.

What are the signs that my John Deere slip clutch needs adjustment?

Some indicators that your slip clutch may need adjustment include excessive slipping or grabbing, unusual noises or vibrations, and difficulty engaging or disengaging the clutch. If you notice any of these, it is recommended to check and adjust the slip clutch.

Conclusion

In summary, proper adjustment of a John Deere slip clutch is essential for optimal performance and longevity of your equipment. By following the steps outlined in this essay, you can ensure your slip clutch is functioning correctly and avoid costly repairs. However, slip clutches are just one small part of the larger agricultural industry.It is crucial to remember the impact that farming has on our world and the responsibility we have to protect and sustain it for future generations. Let us strive to continuously improve and innovate in the field of agriculture, including proper maintenance and adjustment of equipment like the John Deere slip clutch.